The contractor shall supply and install specified Interserv trunking per tender drawings in Cat 5, 6, 6A and Cat 7 triple, dual or single duct, columns, floor ducts, column surrounds, custom corners and fabrications and standard accessories. Ensure installation standards meet required technical and practical specifications and aesthetic requirements.

Data and power cables shall be run in separate channels in such a way so as to ensure channel capacity/volume and bend radius criteria for compliance with applicable national and international standard are not compromised. Channel depth shall be not less than that required to accommodate the minimum bend radius of the selected cable size when the cable is properly secured in the outlet fitting and the outlet fitting is secured in its final position. Bandwidth and data speed auditing conducted with the outlets standing proud of the skirting is invalid and shall not be accepted. Bend radius shall be determined by reference to national and international standards relevant to the cable in question. If doubt exists refer matter to client/architect

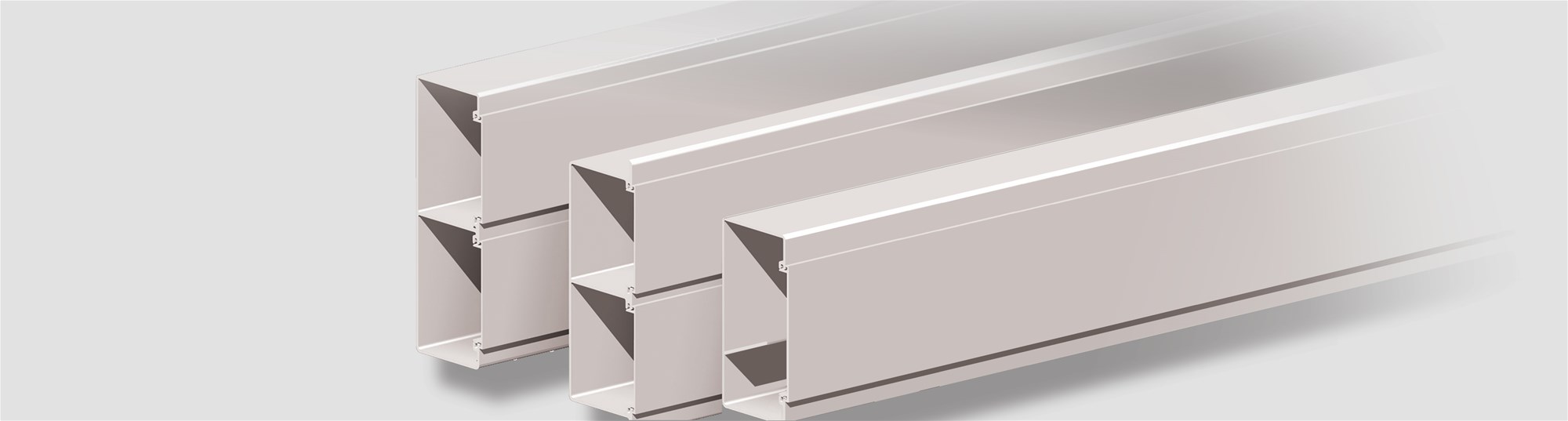

The skirting duct body is to be extruded from aluminium alloy 6060 with T5 temper. It is to be installed with either a natural anodised finish or a powder epoxy coated (EPC) finish to the exposed surfaces, in one of the standard colours nominated by the client/architect.

Standard ex-stock EPC colour from supplier is Penrose White. Natural anodised finish and a wide range of other EPC colours are available. Where skirting may be exposed to the outside elements a colour from an EPC suitable for exterior use such as Dulux Duratec must be used. Allow a suitable lead time for processing and transportation.

The skirting duct body is to be supplied in nominal 3 metre lengths or 6 metre lengths and the cover plates in 3 metre lengths.

The Installer shall ensure straightness and adequate rigidity against twisting and distortion. Straight butt joints are to be secured, aligned and earth continuity achieved with supplier's Joiners. Supplied for use in pairs, plan for one joiner pair per two lengths joined, two pair per corner or bend, three pair per tee junction.

Exposed duct ends are to be fitted with aluminium standard 90o end caps screw fixed or riveted in place, or 45o end caps fixed with joiner plates where the duct end is within 600mm of a doorway.

All external corners are to be fitted with manufactured corner pieces. Installer must ensure that duct abutment faces are accurately cut for length and squareness and that joining pieces top and bottom are positioned so that joins are correctly aligned and earth continuity is ensured.

If duct corners must be mitre-cut work must be done only by skilled tradesmen utilising recommended aluminium cutting and accurate mitre equipment, making certain in all cases that joining pieces top and bottom are positioned so that joins are correctly aligned for aesthetic reasons, and that earth continuity is ensured. All work including earth bonding is to comply with AS/NZ 3000 standards.

Each complete cable trunking run is to be bonded to a common building protective earth. All power circuits within the duct shall be wired with thermoplastic insulated and sheathed (double insulated) cables.

All power and data outlets are to be fixed and earthed securely to duct body. In the standard installation, power, telephone and data outlets are to be directly mounted to Interserv's pre-drilled and tapped outlet fixing plates positioned directly within the trunking lip.